Geometric Dimensioning and Tolerancing (GD&T) is a common symbolic language followed in Engineering industry on Part Drawing. There are many tangible advantages of GD&T over coordinate system dimensioning & tolerancing. We will see following major three advantages contributing to savings.

1. 57% OK parts are recovered which are being rejected based on coordinate system dimensioning and tolerancing? resulting increase in acceptance level and subsequently reduces Cost per piece.

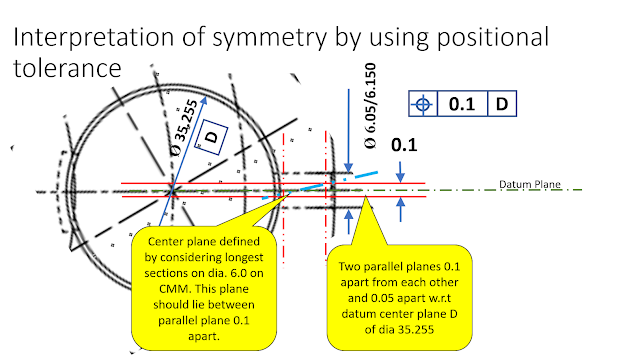

Figure 1

Above figure depicts square tolerance zone 0.2 X 0.2 for position of hole dia. 15.3/15.4 as per coordinate measurement system. Actual positions of holes on all manufactured parts should lie between square tolerance zone 0.2X0.2. Any hole found outside this tolerance zone will get rejected. In above figure all yellow & green centers of the holes are within this acceptable tolerance zone. If you observe carefully, all centers of holes positioned at apex of square are farthest from nominal center of hole ie. at a distance of 'a'. But all red centers are out of acceptable square tolerance zone and are rejected as per current coordinate system in spite of they are at distance 'a'. Practically all holes having red centers are functionally OK and are similar to holes having green centers observed at apex of the square.

This contradiction is addressed by GD&T by accepting all holes located out of square tolerance zone but lying within circle of diameter equal to diagonal of square ie 2a. In short GD&T has widened the area of acceptance by 57% which can be geometrically calculated by subtracting area of square from area of circle. Rather we can say now GD&T has accepted 57% functionally OK parts which we were rejecting it as on date as per co-ordinate measurement system. This circle is nothing but round tolerance zone of positional tolerance. This round tolerance zone is addressed as positional tolerance in GD&T, depicted in below figure.

2.GD&T provides more additional tolerance as a bonus for assemblies having loose fitment or having clearance fit. This improves acceptance level of parts in manufacturing.

Another way of increasing acceptance level or reducing PPM defect by exercising bonus tolerance awarded by GD&T. Particularly for clearance fit or loose fitment application designer can apply MMC condition if it is not affecting performance of the final assembled product. It is designers call to apply modifiers for MMC/LMC/RFS based on application, performance & expectation at customer end. If MMC or LMC condition is applicable then manufacturer will get addition tolerance depending on feature of size (FOS). For RFS condition bonus tolerance is not applicable.

Example in fig 2 is the case of MMC modifier applied for positional tolerance of hole dia 15.3/15.4. Following table shows bonus tolerance against size of the hole.

Bonus tolerance is zero at MMC condition and it is maximum at LMC condition. It is 0 at dia. 15.30 (MMC of hole) and 0.38 at dia. 15.40. Bonus tolerance is applicable in GD&T, for coordinate system tolerance is always fixed like RFS in GD&T. Here as per coordinate system tolerance remains 0.20 for any size of hole dia. Ultimately acceptance level of parts is increased in GD&T by exercising Bonus tolerance facility. This would further increase acceptance level and subsequently reduces Cost per piece.

3.Reduction in inspection cost of the part, which is one of the major contributing factor of manufacturing cost.

Once part is designed for MMC condition, designing qualifying gage becomes easy. All qualifying gages are GO type and checks functionality of part. If part rest against datums on gage and easily gets assembled on gage without fouling then part is OK. If part fouls for resting & location then it is rejected. Any unskilled operator can check with training and SOP(Standard Operating Procedure). Qualifying gage checks that part is not crossing worst case boundary defined by MMC & tolerance given in control frame. Subject concept is not applicable in co-ordinate system as tolerance is not depend on feature of size. We need to always check parts by lay out method or CMM. Hourly operating rate of CMM is always very high. Secondly we can not afford 100% inspection by layout or CMM method. Below figure depicts simple qualifying gage for qualifying positional tolerance dia.0.28 for hole dia. 15.3/15.4 at MMC w.r.t. datums A,B and C.

Apart from above three major reasons of reduction in manufacturing cost, GD&T has many other intangible benefits like more clarity and neatness in part drawing, minimum notes in text, common understanding among Design, Production & Quality functions resulting better alignment without any conflict in understanding. Hence, all engineers must learn to apply, read and interpret GD&T effectively as it is a language of 21st century...